PAM-XIAMEN provides InAs wafer ( Indium Arsenide ) to optoelectronics industry in diameter up to 2 inch .

InAs crystal is a compound formed by 6N pure In and As element and is grown by Liquid Encapsulated Czochralski ( LEC ) method with EPD < 15000 cm -3 . InAs crystal has high uniformity of electrical parameters and low defect density , suitable for MBE or MOCVD epitaxial growth .

We have "epi ready " InAs products with wide choice in exact or off orientation , low or high doped concentration and surface finish . Please contact us for more product information .

1)2”InAs

Type/Dopant:N/S

Orientation:[111B]±0.5°

Thickness:500±25um

Epi-Ready

SSP

2)2”InAs

Type/Dopant:N/Undoped

Orientation : (111)B

Thickness:500um±25um

SSP

3)2”InAs

Type/Dopant:N Un-doped

Orientation :A ±0.5°

Thickness:500um±25um

epi-ready

Ra<=0.5nm

Carrier Concentration(cm-3):1E16~3E16

Mobility(cm -2 ):>20000

EPD(cm -2 ):<15000

SSP

4)2”InAs

Type/Dopant:N/Undoped

Orientation :with [001]O.F.

Thickness:2mm

AS cut

5)2”InAs

Type/Dopant:N/P

Orientation :(100),

Carrier Concentration(cm-3):(5-10)E17,

Thickness:500 um

SSP

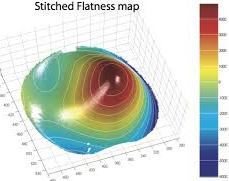

All wafers are offered with high quality epitaxy ready finishing. Surfaces are characterised by in-house, advanced optical metrology techniques which include Surfscan haze and particle monitoring, spectroscopic ellipsometry and grazing incidence interferometry

The influence of annealing temperature on the optical properties of surface electron accumulation layers in n-type (1 0 0) InAs wafers has been investigated by Raman spectroscopy. It exhibits that Raman peaks due to scattering by unscreened LO phonons disappear with increasing temperature, which indicates that the electron accumulation layer in InAs surface is eliminated by annealing. The involved mechanism was analyzed by X-ray photoelectron spectroscopy, X-ray diffraction and high-resolution transmission electron microscopy. The results show that amorphous In2O3 and As2O3 phases are formed at InAs surface during annealing and, meanwhile, a thin crystalline As layer at the interface between the oxidized layer and the wafer is also generated which leads to a decrease in thickness of the surface electron accumulation layer since As adatoms introduce acceptor type surface states.

Relative products:

InAs wafer

InSb wafer

InP wafer

GaAs wafer

GaSb wafer

GaP wafer

Source: semiconductorwafers.net

For more information, please visit our website:http://www.semiconductorwafers.net,

send us email at angel.ye@powerwaywafer.com or powerwaymaterial@gmail.com.

Contact Information

Contact Information luna@powerwaywafer.com

luna@powerwaywafer.com powerwaymaterial@gmail.com

powerwaymaterial@gmail.com  +86-592-5601 404

+86-592-5601 404